Rudloff-StrongForce’s (RSF) prefabricated stairs system offers a comprehensive solution to common quality issues associated with on-site concrete element construction.

With simplified transport, "drop-in" installation, reduced rebar installation requirements, accelerated pour cycles, and efficient finishing, this system enhances project outcomes by addressing common quality issues faced when constructing on-site concrete elements in uncontrolled environments.

By choosing RSF, construction projects can benefit from precision engineering, reduced rework, and a streamlined process that leads to superior results and an accelerated site program.

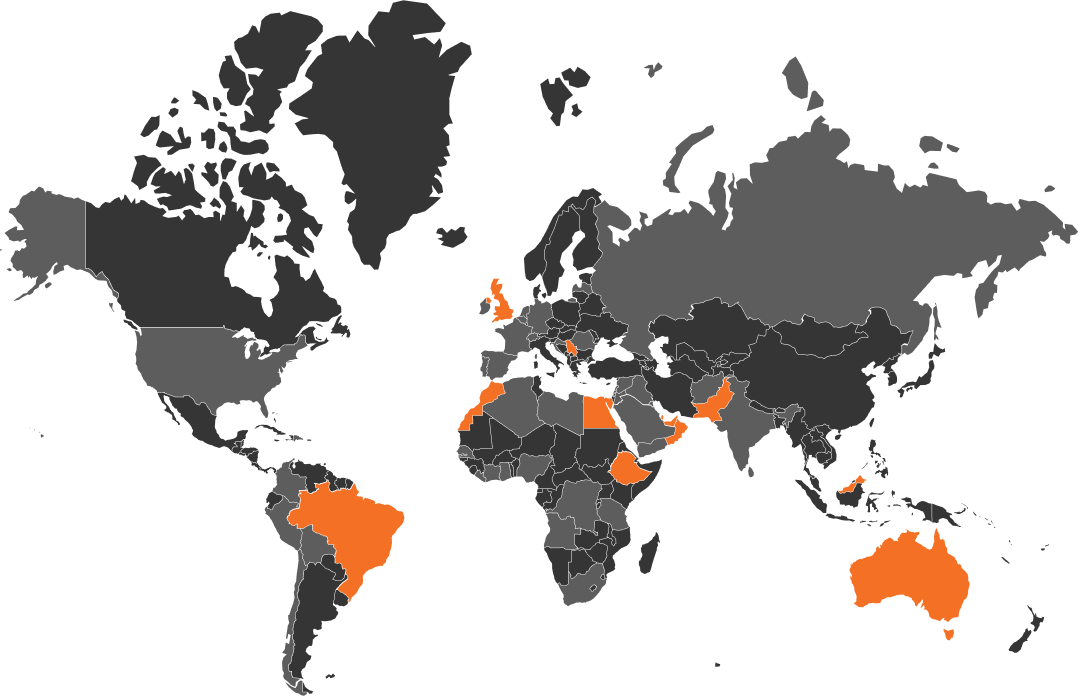

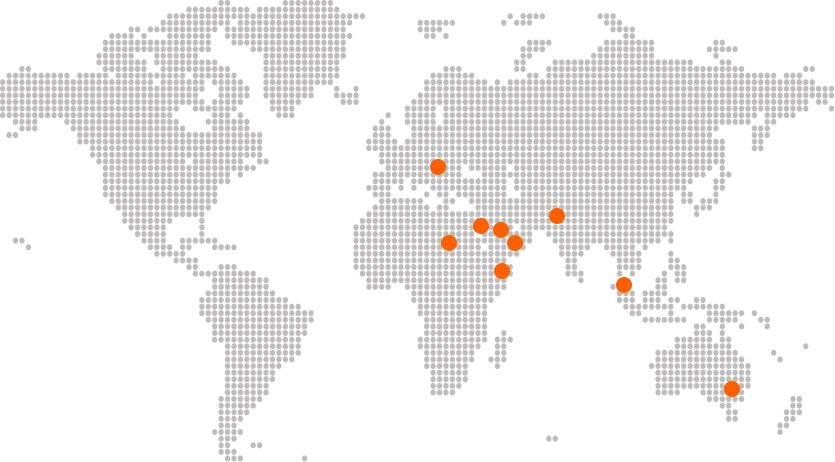

The RSF prefabricated stairs system can be applied to a wide range of residential, industrial, and commercial construction projects. This system is particularly advantageous in projects where on-site construction conditions are challenging or where time efficiency is critical, offering a range of benefits and features that enhance project outcomes.

Key Benefits and Features:

Simplified Transport & Logistics: RSF's prefabricated stairs are designed for ease of transport and logistics. This simplifies the process of getting the components to the construction site, reducing logistical challenges.

"Drop In" Installation at Site: Installing RSF prefabricated stairs is a straightforward "drop-in" process at the construction site. This simplicity accelerates the installation phase and minimizes disruptions.

Rebar Installation Only Required at Platforms: The need for rebar installation is limited to the platforms, reducing on-site labour installation requirements.

Accelerated 2-Day Pour Cycle: The RSF system allows for an accelerated two-day pour cycle, significantly reducing the time required for concrete casting, accelerating the site program when comparing to conventional methods and precast.

Efficient Finishing: The finishing process is streamlined with only one coat of epoxy paint required, commonly applied after 12 months. This approach ensures a durable and aesthetically pleasing finish.

No Reworks or Remedial Works: RSF's prefabricated stairs are precision-engineered, resulting in a perfect concrete level finish within tolerance. This eliminates the need for time-consuming reworks or remedial works, saving time and resources.

Shop Drawings Produced by RSF: RSF takes care of the shop drawings, ensuring that the components are accurately manufactured to meet project specifications.